Latest NBN NewsNewcastle NewsSlider

LIFESAVING VENTILATORS MADE IN NEWCASTLE

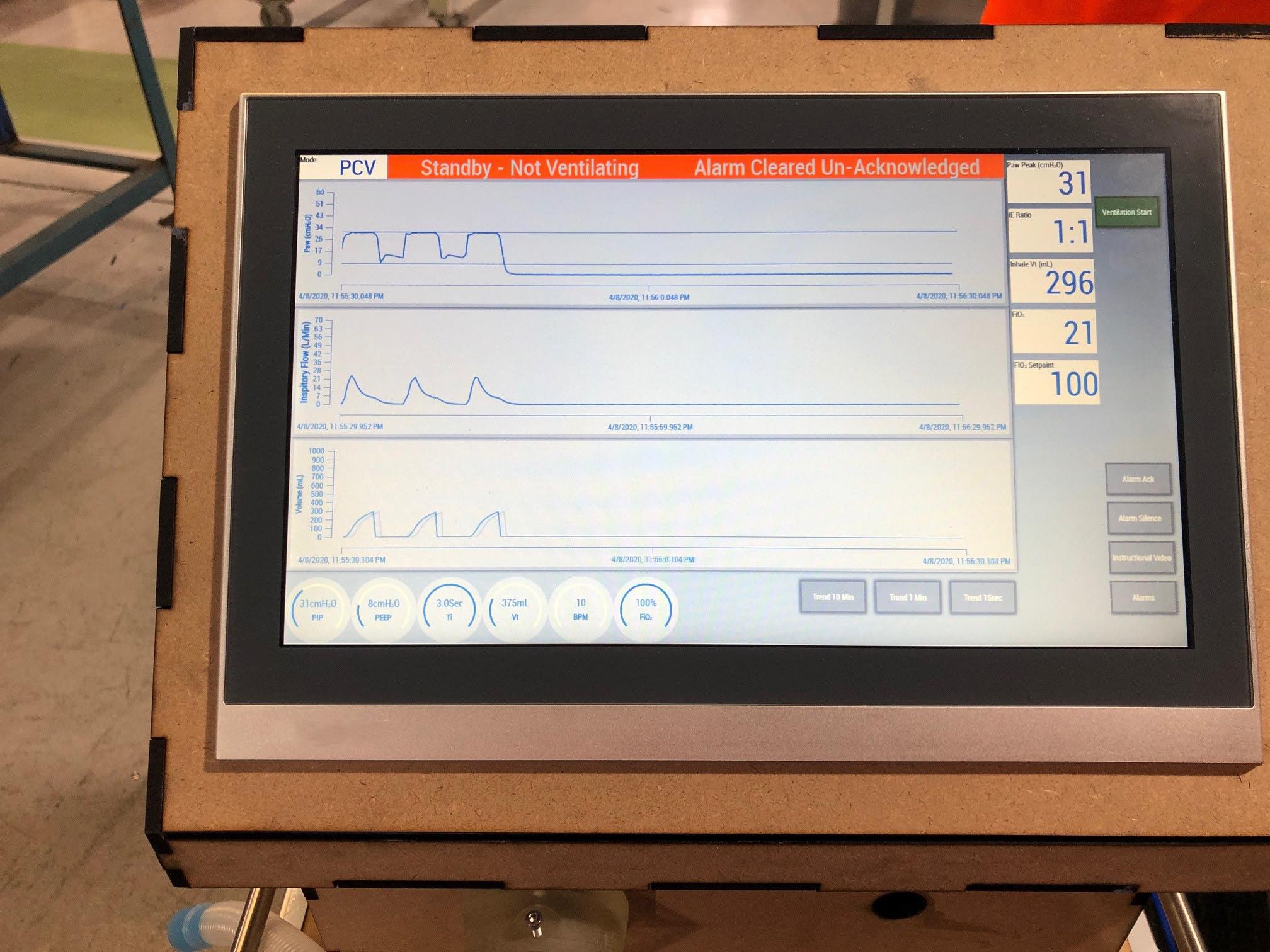

Newcastle manufacturer, Amp Control, is one of two companies developing ventilators which have been in short supply throughout the pandemic.

The prototypes are being designed and built the Hunter engineering company and by a group of students from the University of Sydney.

NSW Premier Gladys Berejikilian said the prototypes would help bolster the nation’s supply of ventilators.

“We know with the easing of restrictions there could be a rise in COVID-19 infections and if a second wave hits, we want our hospitals to have all the equipment they need,” Ms Berejiklian said.

“Pleasingly, five groups came forward to produce ventilator prototypes after our callout to industry, with two of those now selected for pre-production.

“If those models are confirmed to align with Therapeutic Goods Administration (TGA) requirements full production can commence, if our hospitals require more ventilators.”

Health Minister Brad Hazzard said NSW is doing all it can to combat global shortages of vital medical equipment.

“To have local manufacturers who are able to supply much-needed equipment to support frontline health workers – in this case a consortium led by the University of Sydney and another by Newcastle-based AmpControl – is absolutely invaluable,” Mr Hazzard said.

The NSW Government invested an extra $800 million to support NSW Health during the COVID-19 crisis, with $10 million going towards pilot projects to produce critical medical equipment.

Minister for Jobs, Investment and Tourism Stuart Ayres said the universities and industry groups involved will produce 10 units of each ventilator for further testing.

“Should these models be successful in completing the pre- production phase, they could not only benefit patients here but overseas, saving lives as well as creating jobs,” Mr Ayres said.

“This ventilator program is a great example for others to follow. It shows how NSW manufacturers are adapting and upskilling to bolster the economy and employment.”

Pre-production is expected to take around six weeks and if a shelf-ready model complies with the necessary regulatory requirements, full production can begin.

Reporter Jacinta Lee will have more on this tonight at 6pm.

text will be replaced